Air Hospital Module

Aeronautical R&D Projects under Lesser Open License 1.3

Revolutionizing Aerial Medical Services: The BeePlane Hospital Module

In the realm of aeronautical advancements, the integration of healthcare facilities into aircraft design represents a transformative shift towards improving global emergency and medical services. At the forefront of this innovative frontier is the BeePlane hospital module, a concept developed under the guidance of Technoplane SAS and protected under the Lesser Open License 1.3. This groundbreaking project aims to redefine how medical aid is delivered in various scenarios, from disaster relief to standard patient transport.

20130117_Bee-Plane_-_Hopital_v1-4 Concept and Development

The BeePlane hospital module was conceptualized during the Technology Readiness Level 1 (TRL1) phase, with the first designs crafted by students from Estaca Laval in 2012/2013. The design features a detachable fuselage specifically equipped for medical use, which can be quickly adapted to the main BeePlane structure as needed. This flexibility ensures rapid deployment capabilities crucial in emergency scenarios.

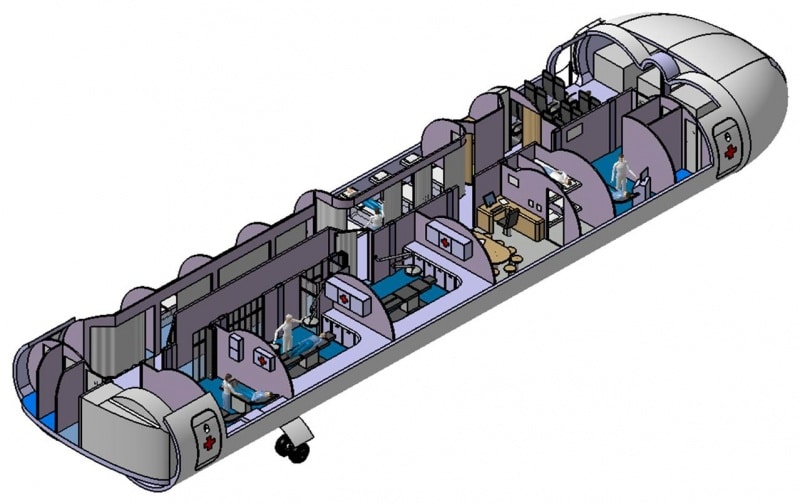

The hospital module includes two surgical units positioned at the rear, a regular medicine area at the front, and a crew rest area strategically placed in the middle. The layout is designed to maximize the efficiency of medical operations while airborne. Accommodation facilities within the module include single bed rooms and a four-bed room, designed to provide care for multiple patients under various medical conditions.

Design Features and Innovations

One of the most distinctive features of the BeePlane hospital module is its modular design. This allows for various medical configurations depending on the specific mission requirements, whether it be a large-scale disaster response or a smaller, more focused medical evacuation. The modularity also facilitates easier maintenance and upgrading of medical equipment, keeping the airborne hospital at the cutting edge of medical technology.

The use of a detachable fuselage not only enables quick transformation from passenger or cargo service to a medical facility but also significantly reduces the time needed to prepare the aircraft for different types of missions. This is crucial in saving lives, where every second counts.

Hopital

Hospital basket has been defined during TRL1.

First drawings have been realized by Estaca Laval in 2012/2013.

20130117_Bee-Plane_-_Hopital_v1-4

Two chirurgical unit on the back, regular medecine in front, crew rest area in the middle. Single Bed rooms and one four beds room

Bee-Plane Hospital Configuration: Transforming Aerial Medical Services with Detachable Fuselages

Revolutionizing the landscape of aerial medical services, the Bee-Plane project offers an aircraft with a detachable fuselage, akin in size to an Airbus A321. Capable of carrying 200/220 passengers and an overall load of 100 tons, the aircraft presents transformative potential for hospital applications.

Project Specifications

Aircraft Capabilities

- Passenger Capacity: 20 PAX

- Patient Beds: 8+3

- Surgical Units: 2

- Radiology Suite: Included

- Crew Beds: 4

Space Allocation

- Front Storage Area (AV Zone de stockage): Dedicated space for storing essential medical equipment.

- Consultation and Radiology Suite (Salle de Consultation et radio AV): A designated area for patient consultation and radiology procedures.

- Crew Rest Area: 4 beds available for the medical crew to rest.

- Surgical Units (Bloc 1 & Bloc 2): Two full-fledged surgical units for emergency medical procedures.

- Rear Consultation and Preparation Room (Salle de consultation et de préparation AR): Additional space for patient consultation and pre-surgery preparation.

- Sanitary Facilities (WC, Douche): Fully-equipped restrooms and a shower area.

- Rear Storage Area (AR Zone de stockage): Additional storage for supplies and equipment.

Supply Chain Management

- JIT Replenishment: A digitized supply chain must be maintained to ensure that essential medical supplies are replenished Just-In-Time, optimizing the aircraft’s turnaround time.

- Quality Control: All equipment and surgical units must meet ISO 13485 standards and undergo regular audits.

- Logistics: Utilize a hub-and-spoke distribution model to ensure seamless integration with ground-based medical facilities.

Regulatory Compliance

- Medical Aircraft Certification: Acquire certification from appropriate aviation and medical regulatory bodies.

- Digital Traceability: Implement digital systems to trace all components back to their origins for compliance with both aviation and healthcare standards.

- Quality Audits: Set up an audit trail that synchronizes with digital supply chain systems.

Advantages and Challenges of Quick-Deploy Detachable Fuselages for Aerial Hospitals

Detachable fuselages in aircraft design have become a focal point of innovation in the aerospace and healthcare industries. While the modular approach carries a range of potential applications, the prospect of creating a quick-deploy aerial hospital stands out as a particularly compelling use-case. This article will focus primarily on the numerous advantages this offers for rapid emergency medical response, while also briefly outlining the challenges that must be considered.

The Advantages of a Quick-Deploy Detachable Hospital Fuselage

- Rapid Deployment: The most apparent benefit of a detachable fuselage configured as an aerial hospital is the unprecedented speed with which medical services can be deployed to disaster-stricken or remote areas.

- Resource Optimization: Detachable fuselages allow for the pre-stocking of medical supplies and equipment.

- Scalability and Modularity: The modular nature of detachable fuselages allows for varying configurations based on specific medical needs.

- Operational Flexibility: A detachable fuselage can be switched quickly from one type of mission to another.

- Cost-Effectiveness: The ability to quickly change configurations can lead to more efficient use of aircraft, reducing operational costs.

Challenges to Consider

- Engineering Complexities: The design and manufacturing of detachable fuselages present unique engineering challenges.

- Regulatory Hurdles: Compliance with both aviation and healthcare regulations is complex.

- Supply Chain Management: JIT delivery of specialized medical modules could stress existing infrastructure.

- Initial Capital Expenditure: The initial investment required for developing these fuselages can be considerable.

The concept of a quick-deploy detachable hospital fuselage offers transformative potential for emergency medical services. While challenges exist, they are not insurmountable, and the long-term gains in terms of lives saved and resources optimized could be substantial.

Visit www.bee-plane.com for more information under Lesser Open Bee License 1-3.