Bee-Plane TRL3

Redefining Aviation with Detachable Fuselage Technology

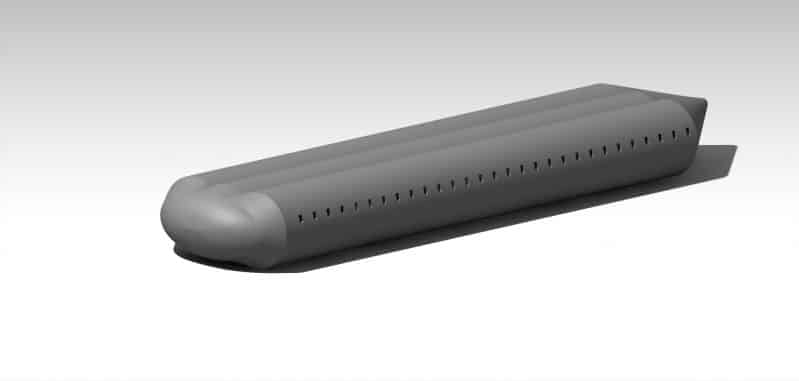

We’re reshaping the future of aviation through an innovative medium-range aircraft featuring a modular, detachable fuselage system. This revolutionary concept rethinks traditional aircraft design, making maintenance, configuration, and turnaround operations significantly more efficient.

Project status: TRL3 – Collaborative Innovation

Our TRL3 (Technology Readiness Level 3) journey began in 2021 and has evolved into a structured and collaborative research phase that is still ongoing.

Over the past years, the project has undergone major architectural refinements — including the transition to a twin bi-open rotor propulsion system — and extensive multidisciplinary work across aerodynamics, structure, modular integration, and operational concepts.

TRL3 has enabled the validation of core principles: the detachable fuselage architecture, structural integration strategies, aerodynamic feasibility, and preliminary operational scenarios. The project is now consolidating these results while preparing the transition toward higher maturity levels (TRL4 and beyond).

Partners: Estaca (Saint-Quentin, Laval, Bordeaux), École Centrale Lille, Lycée Diderot, Lycée Louis Armand, Ecole Centrale Supelec, Ensta Paris, Lycée Diderot and many more.

Engineering for the Future

This stage of development focused on concept validation, collaborative simulation, and academic-industrial synergy. Every design aspect was challenged and refined with input from top French engineering schools.

TRL3 isn’t just a milestone—it’s a testbed for the collaborative spirit embedded in the BeePlane philosophy.

Explore the Bee-Plane Wiki

Go deeper into the Bee-Plane concept through our dedicated Wiki. Discover the design milestones, technical architecture, and the academic partnerships fueling this disruptive vision in aviation.

Bee-Plane is a collaborative R&D program currently in TRL3, focused on developing a medium-range modular aircraft featuring a detachable fuselage.

- Project website : www.bee-plane.com

- License : Lesser Open Bee License v1.3

- University Network : Aeronautical Universities

Aeronautical Projects & Open Licensing

Bee-Plane™ proudly contributes to the aeronautical ecosystem through a structured open-innovation approach.

Since 2013, our research and collaborative work have been distributed under the Lesser Open Bee License 1.3, fostering knowledge sharing, academic contribution, and transparent engineering development.

The foundations were established in 2012 with Bee-License 1.2.

In 2013, Bee-License 1.3 became the reference framework, enabling structured collaboration and direct contributions from four partner universities during the project’s first academic cycle.

Bee-Plane™: Innovation in Action

The Bee-Plane initiative has reached TRL3, marking the validation of key technological principles through analytical studies, digital simulations, and collaborative engineering work.

The project has progressed through structured academic and industrial cooperation, enabling the validation of core design concepts — including the detachable fuselage architecture, structural integration strategies, and the transition to a twin bi-open rotor configuration.

This initiative continues to exemplify our licensing philosophy: shared research, mutual advancement, and open, traceable contributions under the Lesser Open Bee License framework.

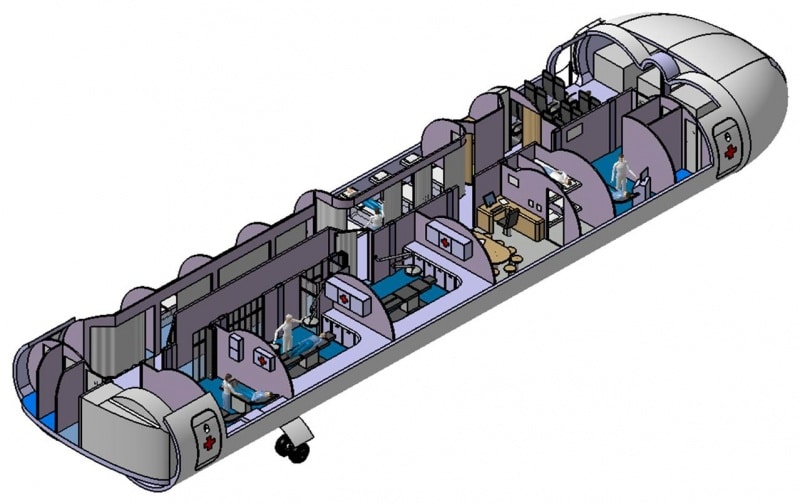

Redefining Airborne Medical Care

nnovation at Bee-Plane™ goes beyond aircraft design. The Hospital Basket is conceived as a fully modular airborne medical unit, integrated into the detachable fuselage architecture and compatible with the current bi-open rotor platform.

Initially explored during the early TRL1 phase (2012–2013), the concept has since evolved within the TRL3 framework to align with updated structural, integration, and operational requirements. The medical configuration includes:

- Dedicated surgical units located in the rear section

- General consultation and triage areas at the front

- A modular central zone configurable with single-bed and multi-bed medical rooms

- Crew rest and support areas integrated into the layout

Designed for rapid deployment and operational flexibility, the Hospital Basket can function both in-flight and as a ground-based medical module once detached, supporting emergency response, humanitarian missions, and military medical operations.

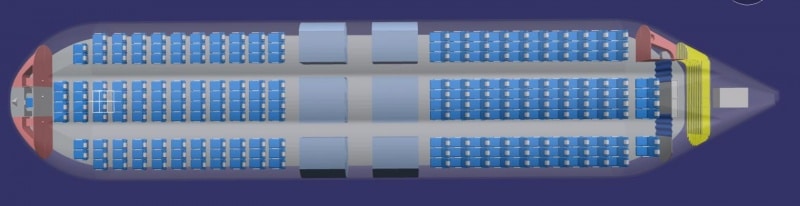

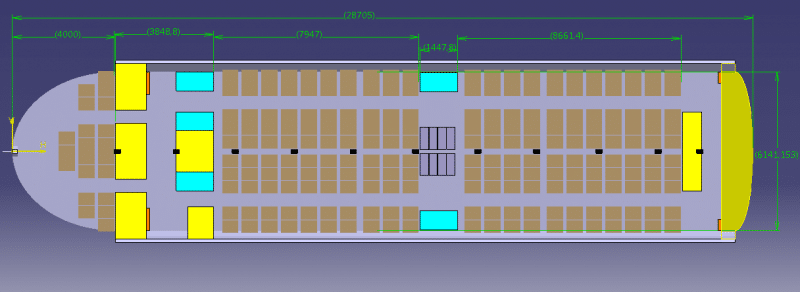

Passenger Comfort Reimagined

Bee-Plane’s passenger module has been designed with long-range comfort in mind. With its triple-pressure bubble structure and optimized layout for 220 passengers, this cabin balances safety, space and functionality.

The cabin includes two aisles, front/middle galley areas, central exits under wings, and luggage walls that double as reinforcement structures. Main access doors are located on both sides for smooth boarding.

Looking Ahead

As TRL3 nears completion, BeePlane’s mission intensifies: from advancing modular fuselage designs to embracing hybrid-electric propulsion and exploring sustainable fuel systems, our goal is clear — shape the next generation of efficient and sustainable aircraft.

We’re building a network — inviting academic labs, industrial leaders, and technology providers to join this vision. Together, we’re redefining the rules of aviation through innovation, collaboration, and purpose-driven engineering.

BeePlane® – A Registered Trademark

BeePlane® symbolizes our values: precision, adaptability, and ambition. The brand encapsulates years of engineering excellence and a bold vision for future-ready aerospace design.

© Technical Coordinator Technoplane SAS – Join us in building a smarter, faster, greener aviation future.

BeePlane – Where Innovation Takes Flight.